Mesh Decimation Benchmark: QEM vs. Vertex Clustering

A rigorous statistical comparison of mesh decimation algorithms using Python and PyMeshLab. Discover which algorithm wins for speed vs. fidelity at different reduction levels.

This study provides empirical evidence that mesh simplification algorithm selection must be informed by both the source topology and the target decimation ratio. Given the widespread use of mesh decimation in game engines, VR/AR applications, and 3D printing pipelines, understanding when to use which algorithm is critical.

GitHub Repository · Full Report (PDF)

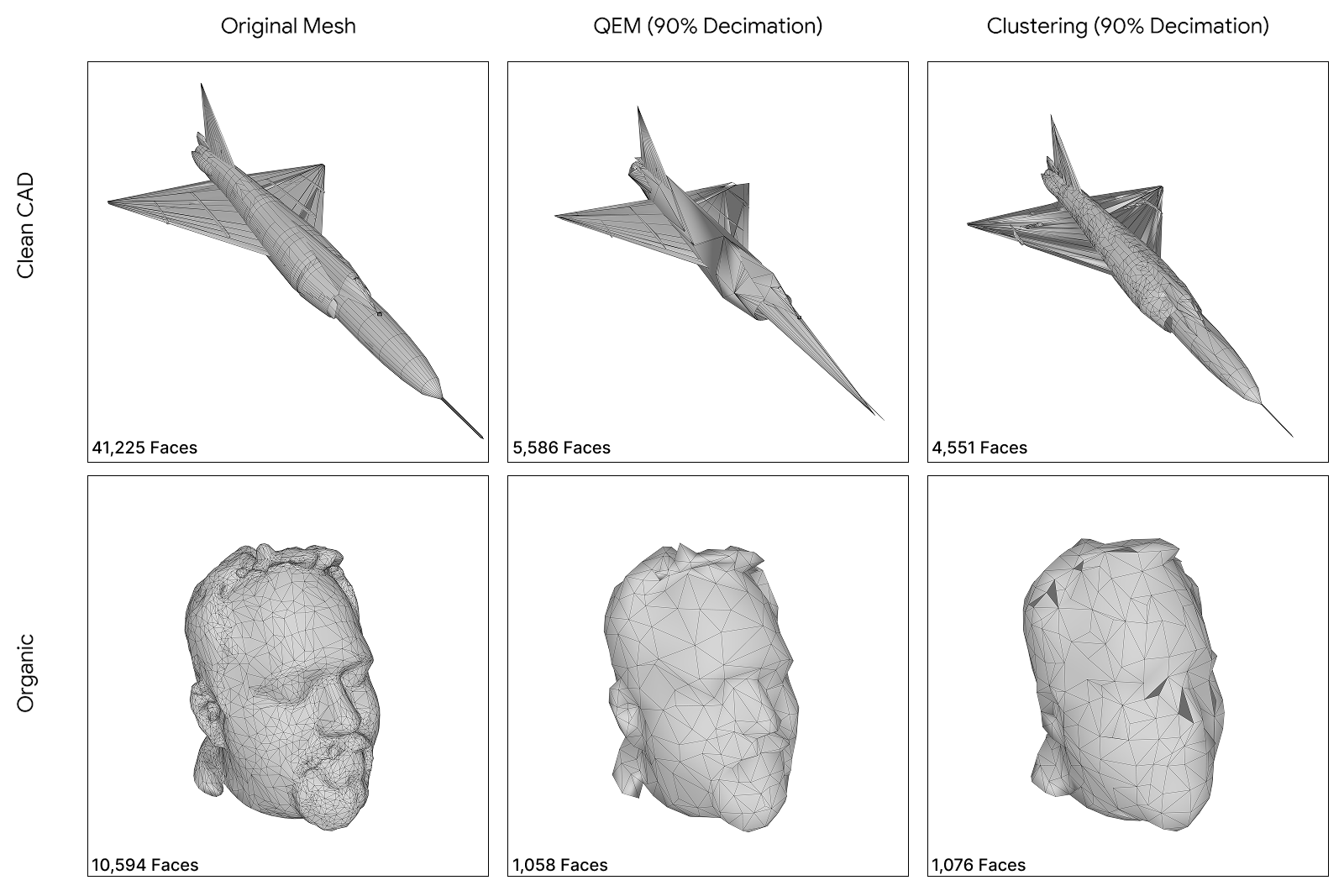

Figure 1: Visual comparison of decimation results. Top row shows Clean CAD models (ModelNet40), bottom row shows Organic Scanned meshes (Thingi10k). QEM struggles with CAD topology at 90% reduction while Clustering maintains global shape.

Key Findings

Our results support all three research hypotheses with strong statistical significance:

Finding 1: Universal Speed Advantage. Vertex Clustering is 60–80× faster than QEM across all conditions (). For a typical organic model with 300k vertices, Clustering completes in ~0.03 seconds (suitable for real-time LOD at 60 FPS), while QEM requires ~1.29 seconds (acceptable only for offline preprocessing).

Finding 2: Topology-Conditional Fidelity. QEM's geometric accuracy advantage is highly conditional. It offers superior fidelity on organic surfaces (mean Hausdorff Distance = 0.006 vs. 0.013 for Clustering), effectively halving the error. However, it catastrophically fails on sparse CAD geometries at 90% decimation (mean HD = 0.034), performing significantly worse than Clustering.

Finding 3: Stability vs. Optimality Trade-off. Clustering exhibits remarkable error stability (coefficient of variation ) across all conditions, whereas QEM's error variance increases by 300% when applied to unsuitable topologies.

Methodology

We utilized a factorial design:

- Factor 1: Algorithm — Quadric Edge Collapse Decimation (QEM) vs. Vertex Clustering

- Factor 2: Mesh Type — Clean CAD (ModelNet40) vs. Organic Scanned (Thingi10k)

- Factor 3: Decimation Level — Moderate (50%) vs. Extreme (90%)

Datasets

We curated a balanced dataset of 30 models to mitigate selection bias:

- Clean CAD: 15 models from ModelNet40. Man-made objects (airplanes, chairs, guitars) with sharp edges, large planar surfaces, and 18k–80k vertices.

- Organic Scanned: 15 models from Thingi10k. 3D scans of sculptures, animals, and characters with smooth curvatures, 10k–600k vertices, and surface noise typical of scanning.

Metrics

- Execution Time: Wall-clock time with warm-up runs and 5 measured repetitions using

time.perf_counter_ns() - Geometric Fidelity: Two-sided Hausdorff Distance , measuring maximum deviation between original mesh and simplified mesh

Statistical Analysis

Three-way ANOVA with Tukey HSD post-hoc tests. Significance level , 95% confidence intervals. Total of 120 observations across the factorial design.

Algorithm Background

Quadric Error Metrics (QEM)

QEM is a high-quality decimation algorithm that iteratively collapses edges to minimize geometric error. Each face incident to a vertex defines a plane, and the error at a vertex is the sum of squared distances to all incident planes:

where is a symmetric matrix. For an edge collapse , the new vertex inherits combined quadrics:

The optimal placement minimizes .

Complexity: due to priority queue maintenance.

Vertex Clustering

Vertex Clustering is a fast, low-memory technique using spatial hashing:

- Compute bounding box and divide into uniform 3D grid cells

- Map each vertex to cell index:

- Collapse all vertices within a cell to representative vertex

- Remove degenerate faces

Complexity: with constant-time bin assignments.

Results

Summary Statistics

| Algorithm | Mesh Type | Time (s) | Hausdorff Dist. |

|---|---|---|---|

| Clustering | Clean CAD (ModelNet40) | 0.005 ± 0.004 | 0.006 ± 0.006 |

| Clustering | Organic (Thingi10k) | 0.032 ± 0.062 | 0.013 ± 0.012 |

| QEM | Clean CAD (ModelNet40) | 0.259 ± 0.178 | 0.034 ± 0.061 |

| QEM | Organic (Thingi10k) | 1.290 ± 1.718 | 0.006 ± 0.007 |

Table 1: Mean ± SD across all decimation levels. Lower Hausdorff Distance indicates better geometric preservation.

Execution Time Analysis

The three-way ANOVA revealed a statistically significant main effect for Algorithm:

The Algorithm × Mesh Type interaction was also significant (, ):

- Clustering: under 0.05s regardless of input complexity

- QEM: 0.26s (CAD) → 1.29s (Organic) — a ~40× performance gap

This gap arises from QEM's priority queue maintenance requiring heap updates per edge collapse, whereas Clustering performs constant-time spatial hashing.

Geometric Fidelity Analysis

Significant effects for Algorithm (), Mesh Type (), and Decimation Level (). The Algorithm × Type interaction was significant ().

Critical finding: QEM catastrophically fails on CAD models at 90% decimation.

Failure case analysis:

- Wing Collapse (Airplane Model): QEM eliminates thin planar surfaces defining wings—quadric error cannot distinguish "safe" interior edges from silhouette-critical boundaries

- Leg Detachment (Chair Model): Supporting columns with 200–300 vertices disappear as QEM prioritizes the larger seat surface

Clustering's voxelization maintains coarse volumetric approximation—appearing "blocky" but preserving global topology.

Effect Size Analysis

Cohen's confirms practical significance:

Execution Time:

- Algorithm effect: (large)

- Mesh Type effect: (medium)

- Algorithm × Type interaction: (very large)

Hausdorff Distance:

- QEM on CAD vs. Clustering on CAD at 90%: (very large)

Practical Recommendations

- Real-time VR/AR: Use Clustering exclusively (ms frame budget)

- Offline CAD simplification at 90%: Prefer Clustering to avoid topological collapse

- High-fidelity organic reduction at 50%: QEM provides optimal surface preservation

- Unknown topology pipelines: Implement hybrid routing based on vertex density

The "one-size-fits-all" approach is suboptimal. Future pipelines should incorporate topology detection as preprocessing to route meshes to algorithm-appropriate strategies.

Limitations

- Non-normality: Shapiro-Wilk tests revealed deviations (, ). ANOVA is generally robust, but p-values should be interpreted with caution.

- Sample Size: (30 models × 2 algorithms × 2 decimation levels)

- Single Error Metric: Only Hausdorff Distance measured

Resources

- GitHub Repository — Full source code

- Full Report (PDF) — Complete paper

- Results Documentation — Statistical analysis

Citation

@misc{annafee2025meshdecimation,

author = {An Nafee, Ahnaf},

title = {Mesh Decimation Benchmark: A Statistical Comparison of QEM and Vertex Clustering},

year = {2025},

publisher = {GitHub},

url = {https://github.com/ahnafnafee/mesh-decimation-benchmark}

}